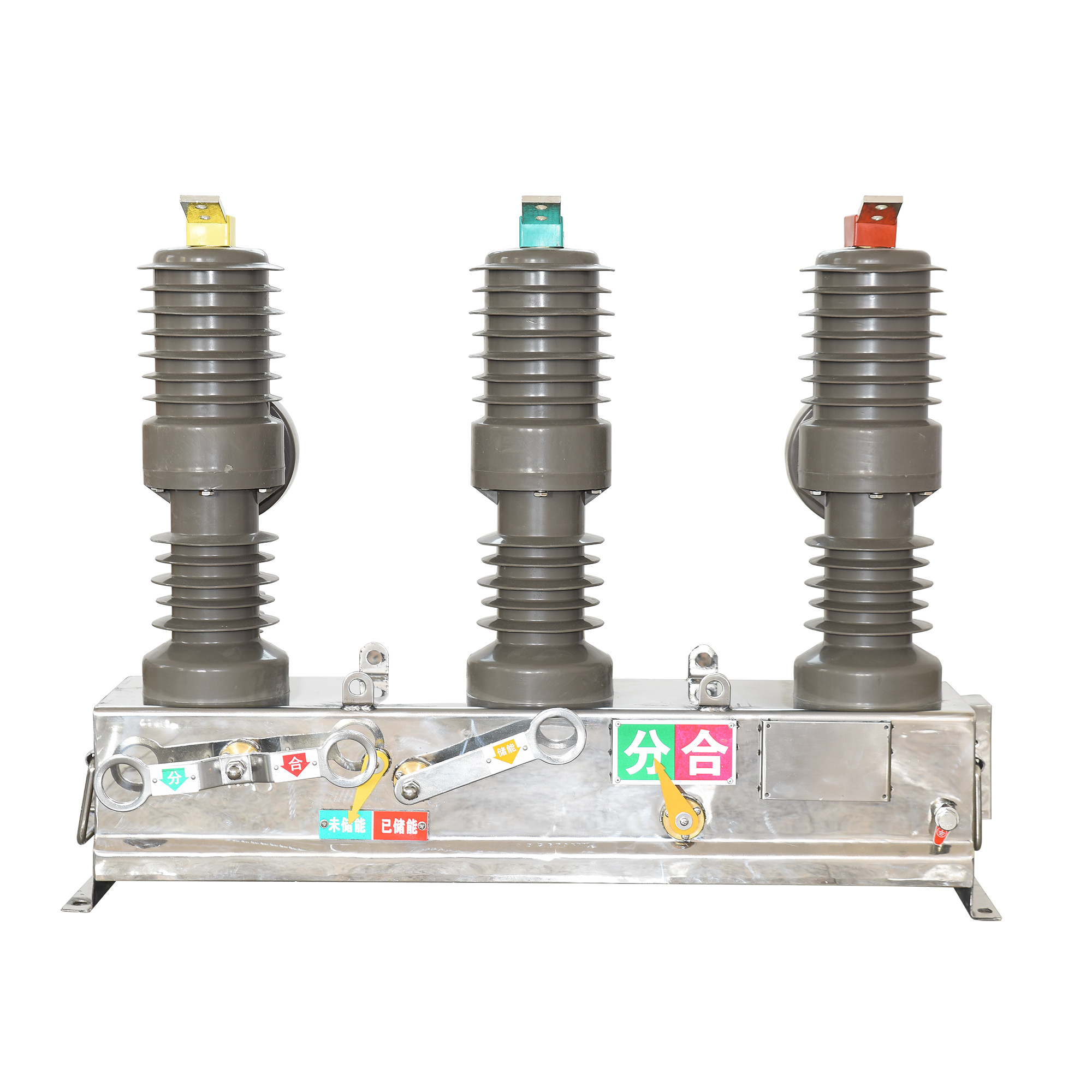

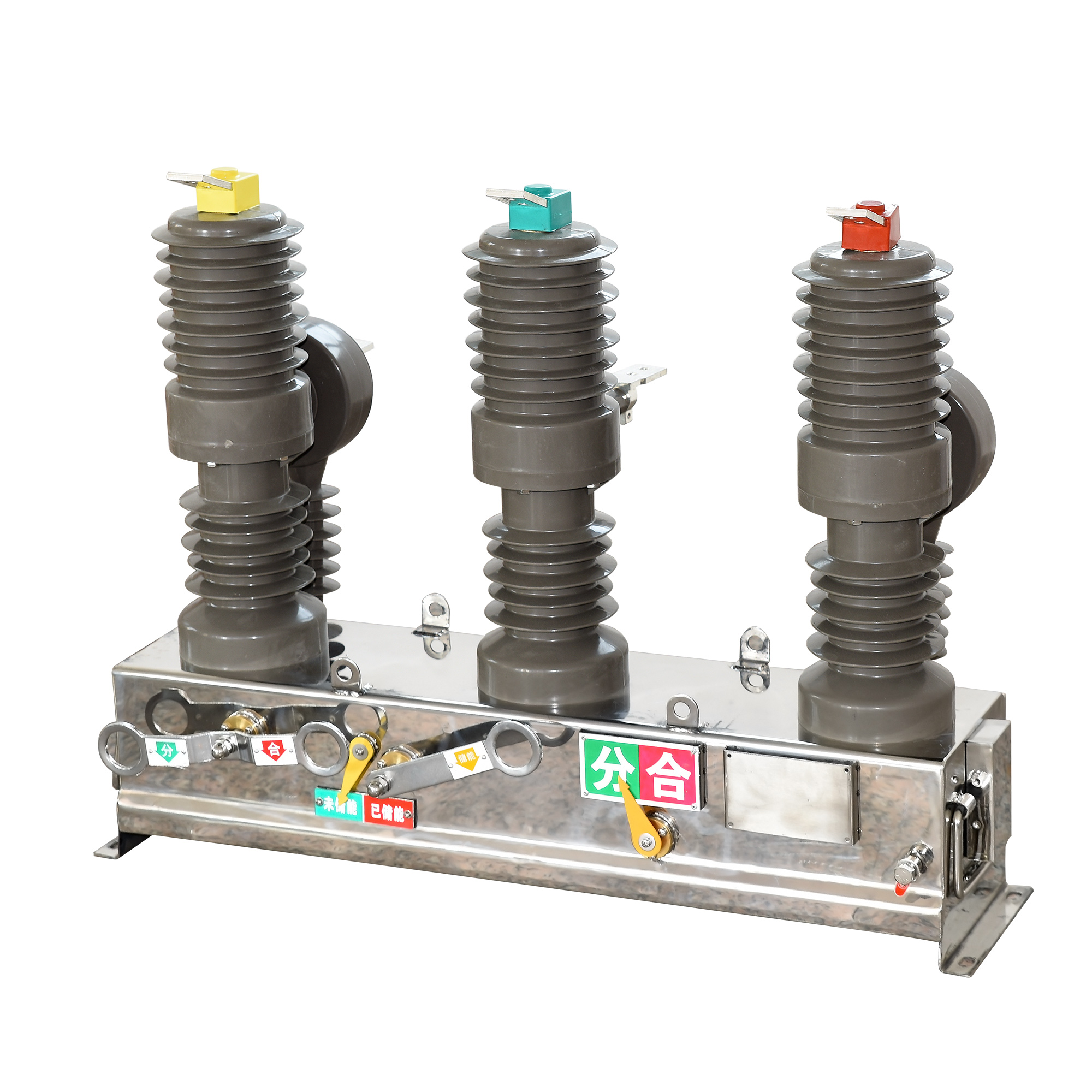

ZW32-12 outdoor vacuum circuit breaker

Others

![]()

Parameters

Details

Size&weight

Related

Video

Message

Product Overview

ZW32-12 outdoor vacuum circuit breaker (hereinafter referred to as "vacuum circuit breaker") is a three-phase AC 50Hz outdoor high voltage switch equipment, mainly used in the 10kV outdoor distribution system of the rural and urban network as the open or close load current, the overload current and the short circuit current, and can also be used in other similar places. ZW32-12 outdoor vacuum circuit breaker meet the national GB 1984-2003, IEC62271-100 "AC high voltage circuit breaker" and GB/T11022-1999 "Common technical requirements for high voltage switchgear and control equipment standards".

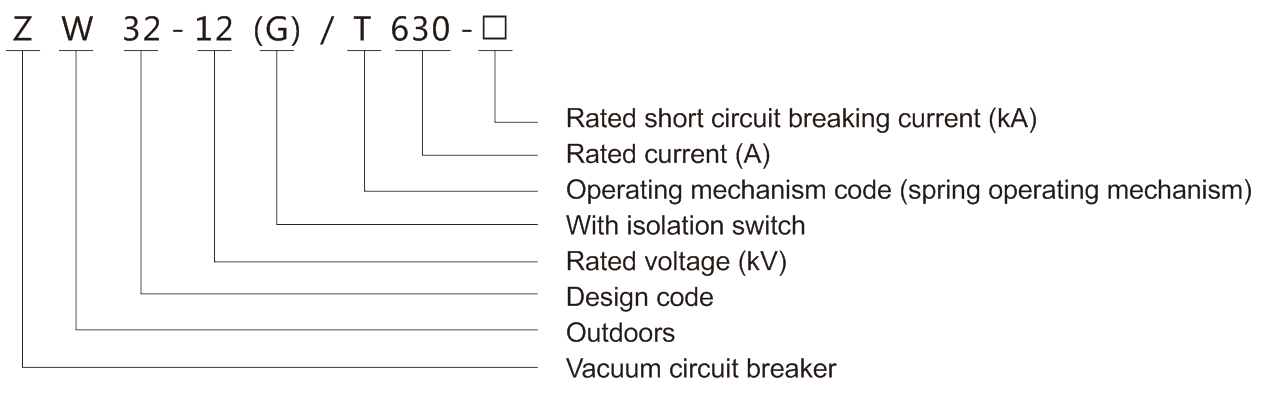

Model and meaning

Normal ambient condition

1. Ambient air temperature: -40°C~+40°C;

2. Altitude: no more than 2000m;

3. The ambient air may be polluted by dust, smoke, corrosive gases, steam or salt fog;

4. The wind speed does not exceed 34m/s (equivalent to 700Pa on a cylindrical surface);

5. Vibration or ground motion from the switchgear and control equipment is negligible;

6. Pollution Grade: Grade III;

7. Outdoor vacuum circuit breaker can be used in the normal use conditions different from the above regulations. At this time, the user should consult with the manufacturer and get the same opinion.

8. If beyond the above normal use conditions, the user will negotiate with the manufacturer.

2. Altitude: no more than 2000m;

3. The ambient air may be polluted by dust, smoke, corrosive gases, steam or salt fog;

4. The wind speed does not exceed 34m/s (equivalent to 700Pa on a cylindrical surface);

5. Vibration or ground motion from the switchgear and control equipment is negligible;

6. Pollution Grade: Grade III;

7. Outdoor vacuum circuit breaker can be used in the normal use conditions different from the above regulations. At this time, the user should consult with the manufacturer and get the same opinion.

8. If beyond the above normal use conditions, the user will negotiate with the manufacturer.

Structure features

1. The breaker uses three-phase post structure whose breaking performance is stable and reliable. It doesn't have combustion and explosion hazard. It doesn't need any maintenance. It also has small volume, light weight and long service life, etc.

2. The breaker uses completely enclosed construction, so its air tightness is good which will contribute to improving damp proof and moist-proof performances. Especially, it is suitable for bitterly cold and moist areas.

3. Pillar and the three-phase current transformer adopts imported outdoor solid insulation epoxy resin, epoxy resin or indoor outsourcing of organic silicon rubber solid insulation; High and low temperature resistance, uv resistance, ageing resistance, etc.

4. Operating mechanism adopts miniaturization of the spring operating mechanism, energy storage motor power is small, points closing low energy consumption; Transmission by using real movement transmission mode, a small number of component parts, high reliability. Operating mechanism under seal regional institutions, solve the problem of the operating mechanism of corrosion, improve the reliability of the institutions.

5. Switching the breaker on and off can be done by manual or electric operation and remote-controlled operation. It can arrive at automated power distribution along with controller. It also can form a coincidence machine and segment machine with coincidence controller.

6. The breaker can be installed with two-phase or three-phase CT, automatic tripping protection for oversupply current and intelligent controller for analysis of information. According to the customers requirement, it also can be installed with measuring CT.

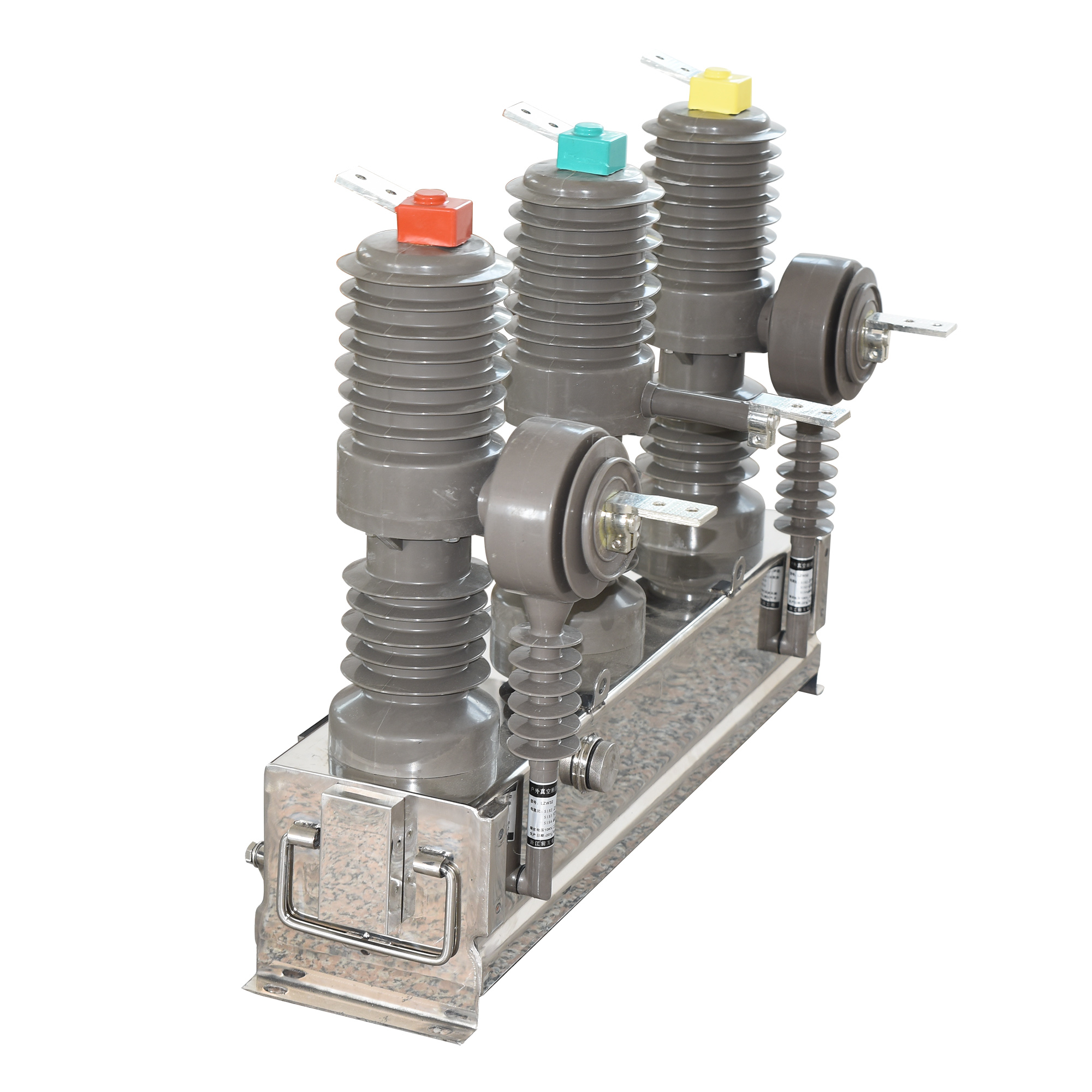

7. Isolation switch with three-phase tandem drive can be installed for the breaker. It has clear visible fracture when the isolating switch is off, and has the anti misoperation interlocking device between the outdoor vacuum circuit breaker body. When the outdoor vacuum circuit breaker is in the closing position, the isolation switch can not be opened and closed; the outdoor vacuum circuit breaker can only be operated when the isolating knife is completely closed or completely opened. Post insulator of arrester is installed. The maintenance is easy and safe.

2. The breaker uses completely enclosed construction, so its air tightness is good which will contribute to improving damp proof and moist-proof performances. Especially, it is suitable for bitterly cold and moist areas.

3. Pillar and the three-phase current transformer adopts imported outdoor solid insulation epoxy resin, epoxy resin or indoor outsourcing of organic silicon rubber solid insulation; High and low temperature resistance, uv resistance, ageing resistance, etc.

4. Operating mechanism adopts miniaturization of the spring operating mechanism, energy storage motor power is small, points closing low energy consumption; Transmission by using real movement transmission mode, a small number of component parts, high reliability. Operating mechanism under seal regional institutions, solve the problem of the operating mechanism of corrosion, improve the reliability of the institutions.

5. Switching the breaker on and off can be done by manual or electric operation and remote-controlled operation. It can arrive at automated power distribution along with controller. It also can form a coincidence machine and segment machine with coincidence controller.

6. The breaker can be installed with two-phase or three-phase CT, automatic tripping protection for oversupply current and intelligent controller for analysis of information. According to the customers requirement, it also can be installed with measuring CT.

7. Isolation switch with three-phase tandem drive can be installed for the breaker. It has clear visible fracture when the isolating switch is off, and has the anti misoperation interlocking device between the outdoor vacuum circuit breaker body. When the outdoor vacuum circuit breaker is in the closing position, the isolation switch can not be opened and closed; the outdoor vacuum circuit breaker can only be operated when the isolating knife is completely closed or completely opened. Post insulator of arrester is installed. The maintenance is easy and safe.

主要技术参数

1. Main technical parameters

2. Assembly adjustment parameter of circuit breaker

3. Main technical parameters of CTB spring operating mechanism

4. ZW32 outdoor vacuum circuit breaker with isolation switch, in addition to meeting the requirements of Table 1, Table 2,

the isolation switch part should also meet the requirements of Table 4.

Operation Principle

1. Principle of manual mechanism operation

■ Closing operation: firstly pull the energy storage handle to store energy, and the applied operating torque increases from small to large. When the closing spring passes through the middle moment, the closing spring releases energy, which urges the energy storage system to rotate counterclockwise and drives the arm to rotate. The drive shaft closes the outdoor vacuum circuit breaker, and at the same time, the split arm catches the opening half shaft to make the circuit breaker in the closing state. When the mechanism is in the closing state, the cam and the rotating shaft sleeve are disengaged, and the mechanism cannot be closed again.

■ Opening operation: After the breaker is closed, pull the opening handle or when the current exceeds the setting value of the anti-surge device, the over-current coil is driven, both make the brake half-axis rotation, the opening arm unbuckle, and the transmission rod makes the circuit breaker opening under the drive of the spring.

2. The principle of motor mechanism

■ Energy storage operation: pulling the energy storage handle, or the energy storage motor rotates, the cam is rotated under the drive gear, and the closing spring is gradually elongated. After the spring passes through, the cam is held by the positioning member and no longer rotates. In preparation for the closing state; at the same time the cam and the drive shaft are disengaged so that the mechanism cannot store energy again.

■ Closing operation: After the energy storage is completed, pull the manual closing handle or apply a voltage to the closing coil to make the closing half shaft rotate. The closing arm and the closing half shaft are unbuckled, and the closing spring releases energy to drive the transmission shaft. The outdoor vacuum circuit breaker is closed and the opening spring is stored. When the mechanism is in the closing state, the energy storage operation is performed again, and the closing spring is again elongated. After the spring passes the middle, the closing half shaft is buckled by the interlocking device to prevent the mechanism from accidentally closing the brake. In the closed state of energy storage, the mechanism is in the reclosing state, which can achieve a "O-0.3S-CO" reclosing operation.

Opening operation: After the outdoor vacuum circuit breaker is closed, the sub-gate handle is pulled or a voltage is applied to the sub-gate coil, or the over-current coil is driven when the line current exceeds the set value of the anti-surge current device, so that the sub-gate is rotated by a half shaft and opened. The arm is released and the transmission lever is opened by the opening spring to open the outdoor vacuum circuit breaker.

Note: The overcurrent coil of the operating mechanism is a short-time working system and cannot be used for a long time.

Over-current protection and mechanism control electrical schematic diagram of circuit breaker shown in Figure 3. (Note: Based on the secondary wiring diagram of the circuit breaker)

■ Closing operation: firstly pull the energy storage handle to store energy, and the applied operating torque increases from small to large. When the closing spring passes through the middle moment, the closing spring releases energy, which urges the energy storage system to rotate counterclockwise and drives the arm to rotate. The drive shaft closes the outdoor vacuum circuit breaker, and at the same time, the split arm catches the opening half shaft to make the circuit breaker in the closing state. When the mechanism is in the closing state, the cam and the rotating shaft sleeve are disengaged, and the mechanism cannot be closed again.

■ Opening operation: After the breaker is closed, pull the opening handle or when the current exceeds the setting value of the anti-surge device, the over-current coil is driven, both make the brake half-axis rotation, the opening arm unbuckle, and the transmission rod makes the circuit breaker opening under the drive of the spring.

2. The principle of motor mechanism

■ Energy storage operation: pulling the energy storage handle, or the energy storage motor rotates, the cam is rotated under the drive gear, and the closing spring is gradually elongated. After the spring passes through, the cam is held by the positioning member and no longer rotates. In preparation for the closing state; at the same time the cam and the drive shaft are disengaged so that the mechanism cannot store energy again.

■ Closing operation: After the energy storage is completed, pull the manual closing handle or apply a voltage to the closing coil to make the closing half shaft rotate. The closing arm and the closing half shaft are unbuckled, and the closing spring releases energy to drive the transmission shaft. The outdoor vacuum circuit breaker is closed and the opening spring is stored. When the mechanism is in the closing state, the energy storage operation is performed again, and the closing spring is again elongated. After the spring passes the middle, the closing half shaft is buckled by the interlocking device to prevent the mechanism from accidentally closing the brake. In the closed state of energy storage, the mechanism is in the reclosing state, which can achieve a "O-0.3S-CO" reclosing operation.

Opening operation: After the outdoor vacuum circuit breaker is closed, the sub-gate handle is pulled or a voltage is applied to the sub-gate coil, or the over-current coil is driven when the line current exceeds the set value of the anti-surge current device, so that the sub-gate is rotated by a half shaft and opened. The arm is released and the transmission lever is opened by the opening spring to open the outdoor vacuum circuit breaker.

Note: The overcurrent coil of the operating mechanism is a short-time working system and cannot be used for a long time.

Over-current protection and mechanism control electrical schematic diagram of circuit breaker shown in Figure 3. (Note: Based on the secondary wiring diagram of the circuit breaker)

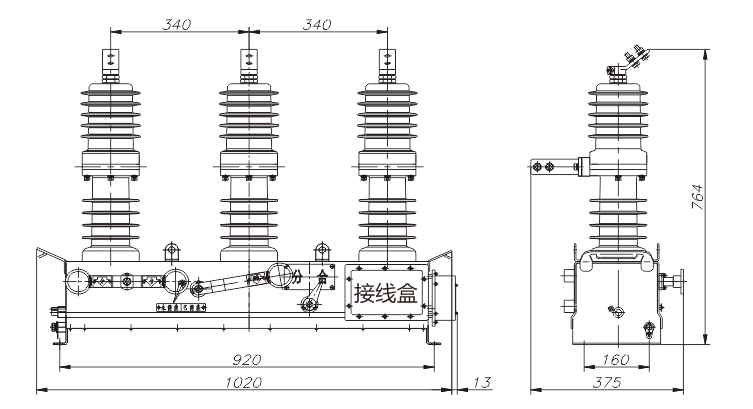

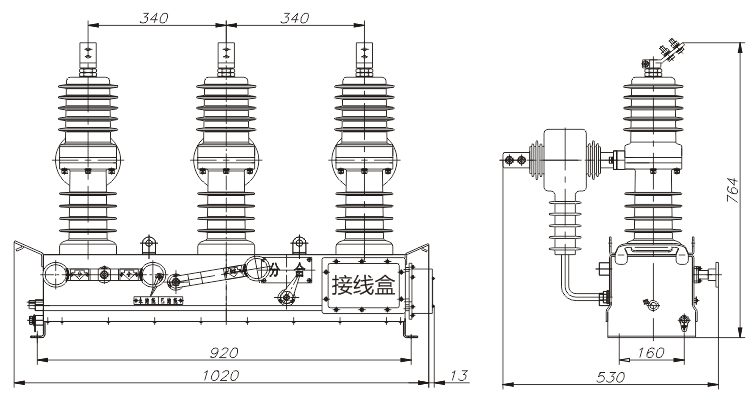

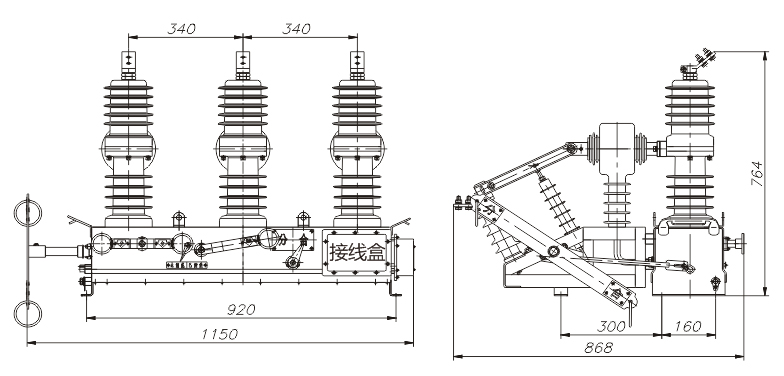

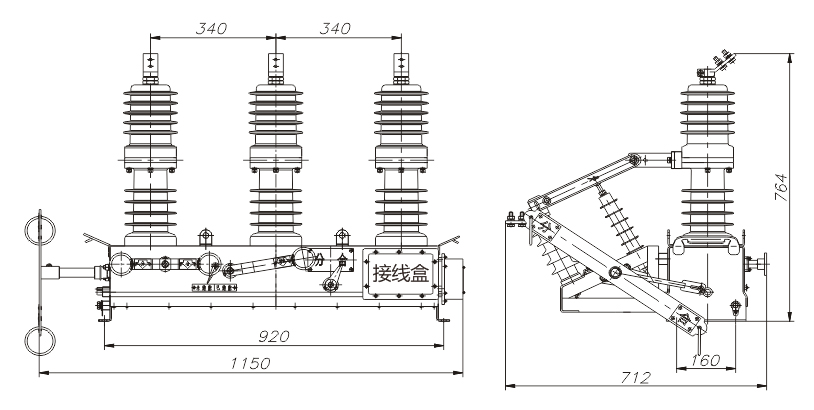

Outline and Installation Dimension

1. Outline dimension of circuit breaker (without CT)

2. Outline dimension of circuit breaker (with CT)

3. Outline dimension of circuit breaker (with CT) with isolator

4. Outline dimension of circuit breaker (without CT) with isolator

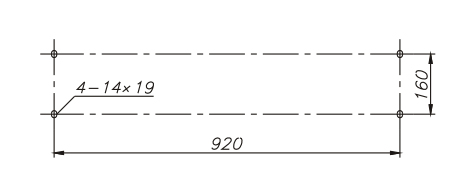

5. Mounting Hole Size of circuit breaker (without CT) with isolator

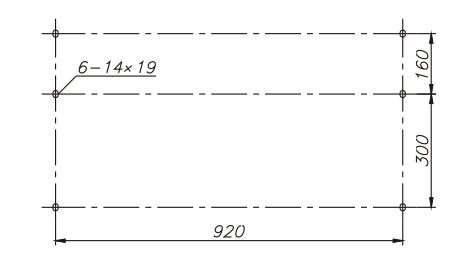

6. Mounting Hole Size of circuit breaker (CT) with isolator

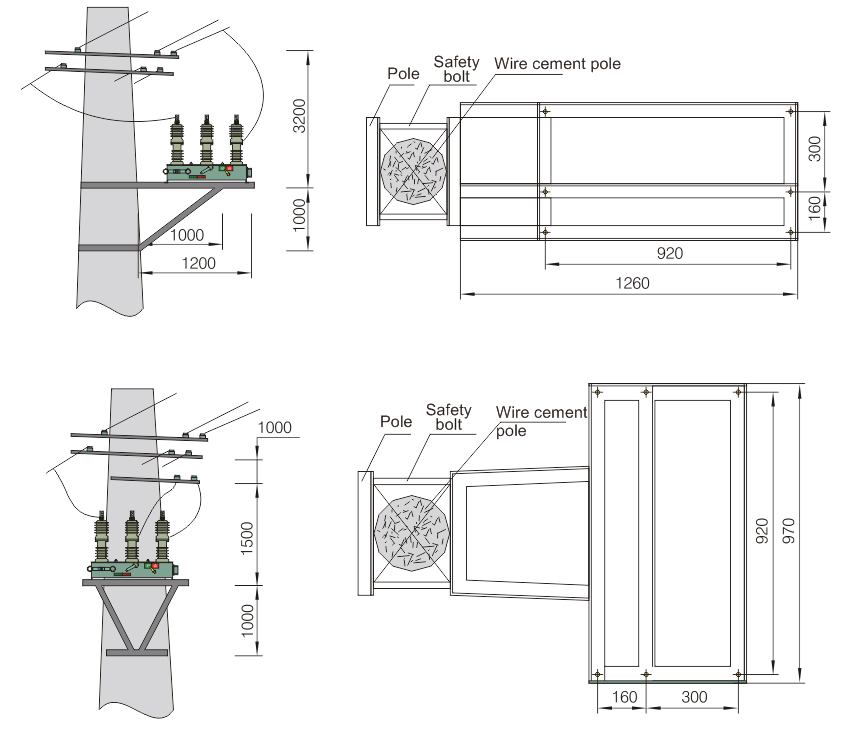

7. Installation diagram of circuit breaker

Installation and maintenance

1. The operator should have a preliminary understanding of the product performance, installation and adjustment, and maintenance knowledge. It should record the problems during operation and notify the manufacturer when necessary.

2. Outdoor vacuum circuit breaker should be visually inspected prior to installation. Check whether the insulation sleeve is damaged, whether there is any leakage in the indication of open-close and storage, whether the box is deformed or not. After inspection, the product should be installed on the posts above 4m.When the circuit breaker with isolator is installed, the accuracy of the mechanical interlocking device between the isolator and the breaker should be carefully checked.

3. Before the product is put into operation, check carefully whether the rated voltage and rated current of each operating element match the actual situation. The mechanism is used to check whether the movements are correct.

4. The parameters of the circuit breaker have been adjusted at the time of factory inspection. Users do not have to turn on the machine for inspection. After the withstand voltage test is performed as required, they can be installed.

5. Outdoor vacuum circuit breaker can be erected by single pole or double pole. Circuit breakers should be mounted smoothly and firmly on special steel frames.

6. The product will be checked regularly to check whether the operation of the circuit breaker is normal. For outdoor vacuum circuit breaker with isolator, the isolator is inspected twice a year, and it is checked whether the mechanical interlocking action between isolator and circuit breakers is normal and some grease is injected into the moving parts.

2. Outdoor vacuum circuit breaker should be visually inspected prior to installation. Check whether the insulation sleeve is damaged, whether there is any leakage in the indication of open-close and storage, whether the box is deformed or not. After inspection, the product should be installed on the posts above 4m.When the circuit breaker with isolator is installed, the accuracy of the mechanical interlocking device between the isolator and the breaker should be carefully checked.

3. Before the product is put into operation, check carefully whether the rated voltage and rated current of each operating element match the actual situation. The mechanism is used to check whether the movements are correct.

4. The parameters of the circuit breaker have been adjusted at the time of factory inspection. Users do not have to turn on the machine for inspection. After the withstand voltage test is performed as required, they can be installed.

5. Outdoor vacuum circuit breaker can be erected by single pole or double pole. Circuit breakers should be mounted smoothly and firmly on special steel frames.

6. The product will be checked regularly to check whether the operation of the circuit breaker is normal. For outdoor vacuum circuit breaker with isolator, the isolator is inspected twice a year, and it is checked whether the mechanical interlocking action between isolator and circuit breakers is normal and some grease is injected into the moving parts.

Transportation, acceptance and storage

■ Transportation

When transporting, the entire product must be packed in a closed box to be fixed. In the transportation process, no turning and tilting must be taken. When lifting the outdoor vacuum circuit breaker body, the four rings hooked on the box can not directly carry the epoxy insulating cylinder. When the outdoor vacuum circuit breaker with isolator, the center of gravity is inclined to the side of the isolating switch, and it should be carried out slowly when lifting.

■ Acceptance

After receiving the outdoor vacuum circuit breaker, the user shall perform the following acceptance work:

1) Check whether the package is damaged or not;

2) Check whether the documents and accessories are complete according to the product packing list ;

3) Check the technical parameters on the outdoor vacuum circuit breaker nameplate and the product certificate meets the order requirements.

■ Storage

The outdoor vacuum circuit breaker shall be stored in a dry, ventilated, moisture-proof, shock-proof and anti-harmful gas-infiltrating room. Check whether the environment meets the requirements if long-term storage. Packing, unpacking and storage should be carried out in a dry room, and check whether the products and components are complete and consistent.

When transporting, the entire product must be packed in a closed box to be fixed. In the transportation process, no turning and tilting must be taken. When lifting the outdoor vacuum circuit breaker body, the four rings hooked on the box can not directly carry the epoxy insulating cylinder. When the outdoor vacuum circuit breaker with isolator, the center of gravity is inclined to the side of the isolating switch, and it should be carried out slowly when lifting.

■ Acceptance

After receiving the outdoor vacuum circuit breaker, the user shall perform the following acceptance work:

1) Check whether the package is damaged or not;

2) Check whether the documents and accessories are complete according to the product packing list ;

3) Check the technical parameters on the outdoor vacuum circuit breaker nameplate and the product certificate meets the order requirements.

■ Storage

The outdoor vacuum circuit breaker shall be stored in a dry, ventilated, moisture-proof, shock-proof and anti-harmful gas-infiltrating room. Check whether the environment meets the requirements if long-term storage. Packing, unpacking and storage should be carried out in a dry room, and check whether the products and components are complete and consistent.

Common faults and troubleshooting

Note: If there are other faults or the above-mentioned faults can not be eliminated, please contact our after-sales service.

view and download

| File name(Click to view) | File type | file size | View times | Click to download |

Product related news

| News title | Promulgator | Release time | View times | Click to read |