Parameters

Details

Size&weight

Related

Video

Message

Product Overview

TXRS online Soft Starter Cabinet is the product that our factory has continuously improved and improved over the years. Soft Starter Cabinet technology has always been in the forefront of similar domestic products. Its built-in multiple relay interfaces make it easy for users to achieve functions of linkage, interlocking, remote monitoring, and one-to-multiple. It is also particularly suitable for the starting and running of fire pump and fan. The constant current starting feature of this machine allows the user to not worry about the current increase caused by heavy load during starting. In fact, this machine can always ensure that the load current does not exceed the set value in any quiet condition (including phase loss, brake).

TXRS constant current Soft Starter Cabinet is a full-function type. When using, it is not necessary to connect the AC contactor in series or in parallel on the main circuit, and it is not necessary to install other protection devices such as phase failure, thermal relay, and fuse on the main circuit. This machine is equipped with complete and reliable electronic intelligent protection, whether it is the phase loss of power supply, phase failure of the motor windings, or phase loss at startup or during operation, the motor will be reliably protected. The reverse time overload protection of the machine will ensure that the motor will be protected by the corresponding process under any overload condition. If the user needs, this machine also has power-saving running function, when the motor is light-load or no-load operation, it can automatically adjust the operating parameters to achieve power-saving operation.

TXRS constant current Soft Starter Cabinet is a full-function type. When using, it is not necessary to connect the AC contactor in series or in parallel on the main circuit, and it is not necessary to install other protection devices such as phase failure, thermal relay, and fuse on the main circuit. This machine is equipped with complete and reliable electronic intelligent protection, whether it is the phase loss of power supply, phase failure of the motor windings, or phase loss at startup or during operation, the motor will be reliably protected. The reverse time overload protection of the machine will ensure that the motor will be protected by the corresponding process under any overload condition. If the user needs, this machine also has power-saving running function, when the motor is light-load or no-load operation, it can automatically adjust the operating parameters to achieve power-saving operation.

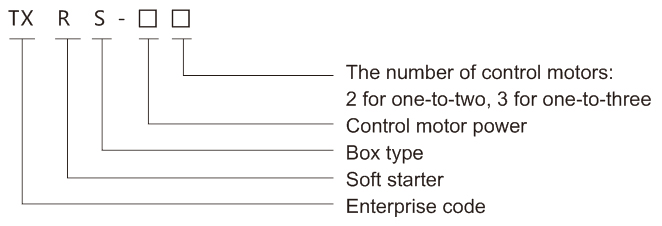

Model and Meaning

Product Features

The unique digital closed-loop high torque control is specially designed for standard loads and heavy loads.

The only in-line soft starter can operate without bypass contactor and can with a bypasse contactor, while maintaining full protection.

Linear control of the supply motor torque during acceleration and deceleration periods (significantly reduces pressure fluctuations)

Easy to adjust the slope and starting torque.

Advanced integrated protection features: over-current, overload, underload, input/output phase overheating.

Plug-in programmable I/O terminals: logic input, logic output, relay output.

Analogue output, 4~20mA.

Motor preheat function.

Built-in motor thermal protection and PTC direct thermal protection.

Two sets of motor parameters are configured and the control parameters are easy to adjust.

Dynamic fault memory.

Load status and running time display.

LCD liquid crystal display.

RS485 communication, standard MODBUS protocol.

The only in-line soft starter can operate without bypass contactor and can with a bypasse contactor, while maintaining full protection.

Linear control of the supply motor torque during acceleration and deceleration periods (significantly reduces pressure fluctuations)

Easy to adjust the slope and starting torque.

Advanced integrated protection features: over-current, overload, underload, input/output phase overheating.

Plug-in programmable I/O terminals: logic input, logic output, relay output.

Analogue output, 4~20mA.

Motor preheat function.

Built-in motor thermal protection and PTC direct thermal protection.

Two sets of motor parameters are configured and the control parameters are easy to adjust.

Dynamic fault memory.

Load status and running time display.

LCD liquid crystal display.

RS485 communication, standard MODBUS protocol.

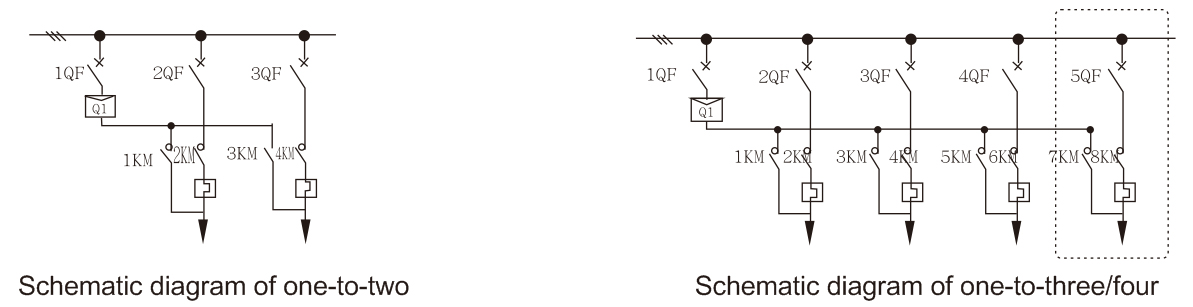

Schematic diagram of primary electric

Main parameters and technical performance

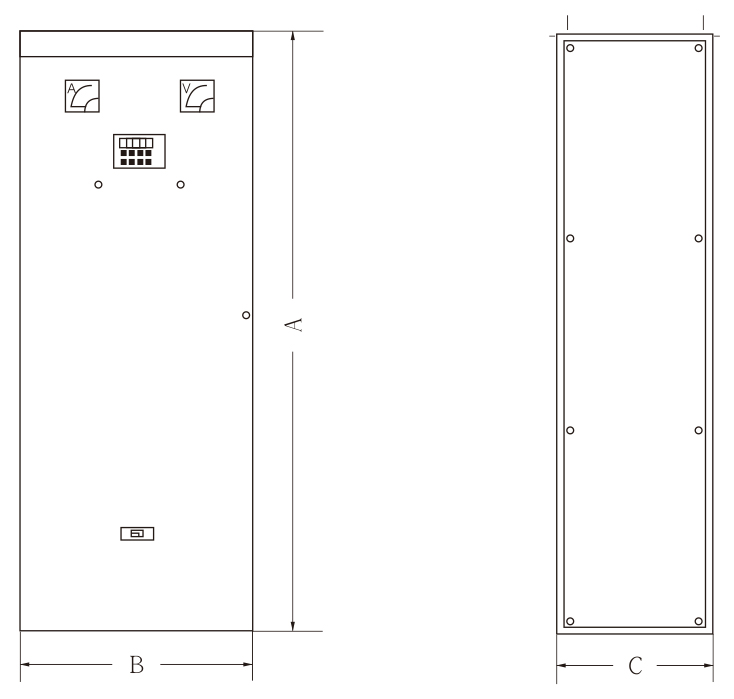

Outline and lnstallation Dimension

view and download

| File name(Click to view) | File type | file size | View times | Click to download |

Product related news

| News title | Promulgator | Release time | View times | Click to read |